3D Filaments Explained: The Most Commonly Asked Questions

What is 3D FIlament?

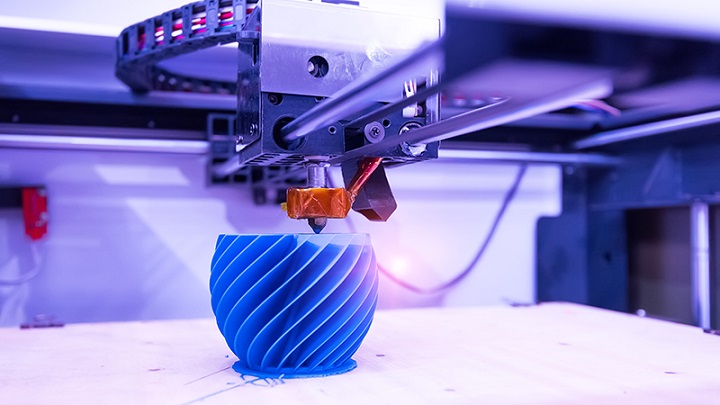

3D filament is the strands of plastic wire that are fed into the 3D printer’s extruder. The extruder then melts the filament and extrudes it onto the bed to create 3D printed objects. When compared to conventional printers, the filaments basically replace the ink. Filaments are now used to create a wide range of items, including electronics, medical devices and functional parts for industrial and commercial mechanical applications. In fact, using 3D printing as a method for prototyping and custom part production is the best way to create prototypes for commercial products.

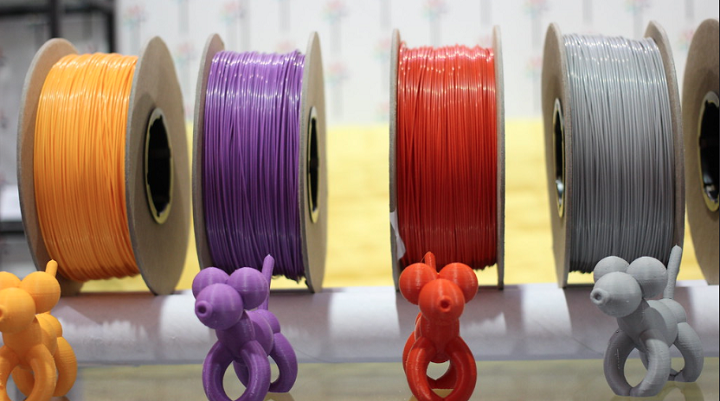

Buying filaments 3D models is a pretty straightforward process, but figuring out which brand to buy from takes some consideration, as not all of them are made the same. There are three key factors to consider when deciding on the best brand – price, filament quality and consistency of tolerance. Customer service and packaging can also make or break your choice, but not as the previously mentioned three factors. Obviously, you want the best filaments 3D options your money can buy, as that will directly affect the quality of your 3D prints. Oftentimes, the quality will be reflected in the price, and as is the case with most things in life, you get what you pay for. And in terms of tolerance, you want a filament with as low tolerance as possible.

What Are the Different Types of 3D Filament?

As 3D printing technology advances, there are more and more types of filament available for consumer use. The most popular types of plastic filament are ABS, PLA, PET, Nulon, TPU, Metal, Wood and Glow in the Dark. All of them have different properties and applications.

PLA is by far the most popular plastic filament used for 3D printing, as it’s easy to work with and it can be used to print most non-functional plastic objects, including jewellery, figurines, pencil holders, etc. PLA is biodegradable, making it an eco-friendly option. It doesn’t warp, it’s non-toxic and doesn’t release any odours when printing.

ABS is another popular filament, it’s commonly used for creating toys for kids, parts for machines and medical devices. The downside to ABS filament is that it’s difficult to work with. It’s affordable, and it features high-temperature resistance. If the hot bed isn’t hot enough, ABS can warp, so it also requires a hotter extruder temperature. Printing with ABS filament should only be done in a well-vented room, as it can release microparticles in the air.

PETG filament is as strong as ABS and as easy to use as PLA, making it one of the most promising types of 3D printing filament on the market. PETG is almost unbreakable, and it will bend instead of snapping like most plastics. It hardly warps and doesn’t release any odour when printing. Further, it bridges well and it’s one of the clearest filaments.

Nylon filament is one of the most versatile printing materials, as it’s strong and flexible when printed in thin layers, but if it’s printed thick – it’s quite stiff. That being said, it’s durable, features a low friction coefficient, high resistance to thermal influences and chemicals. However, it’s sensitive to moisture, so it’s important you keep it dry. But just like any other type of filament, there are various grades of Nylon, some higher than others, so these properties will vary on the type you end up buying.

How to Store Filament?

The ideal way to store 3D filament is in a storage bin that you can buy at large department stores, office supply stores and hardware stores. One thing to make sure when buying these storage containers is that they have air-tight lids to keep humidity out. Many people prefer to get clear bins so that they see which filament is inside without having to open it. Then, place some type of desiccant in the bin. One popular option is a porous bag of rice. Rice is great at absorbing moisture from the environment, so if you put a few cups inside a shoebox or sock inside the bin, it will absorb any humidity, keeping the filament dry. Alternatively, you can get gel packs of silica beads.

Can You Make Filament Yourself?

Yes! Almost all plastic can be recycled into filament with the help of a filament extruder, and some know-how. Once you figure out how to create filament out of plastic, you can use plastic bottles, milk jugs and other plastic items to create 3D printing filament. Furthermore, you can buy plastic pellets that cost only a fraction of the price of filament and extrude them into filament. However, filament extrusion machines aren’t cheap, and they can cost anywhere from $500 to $2000 and more. But if you intend on 3D printing a lot, then investing in one will pay itself out in the long term.