Fire Rated Cables: Heat-Resistant vs. Fire Retardant vs Fire Resistant

With annual average temperatures rising, fires are becoming the norm for much of Australia. Tragic events have cost lives, and building regulations are constantly being expanded to ensure that residential and industrial buildings perform adequately in the case of a fire. Here, particular focus is put towards insulative cladding that extinguishes fires on contact. Many residences and premises however have yet to implement this.

Another area covered in National Construction Codes and International Standards is the use of cabling. In industrial and commercial settings, different cabling is used for different purposes. Where high levels of heat are generated, specific cables allow for the normal operation of production and other facilities. In fire-prone areas, and emergency signalling systems when a fire does occur, the use of fire rated cable will prevent fire from spreading to other areas, and ensure that evacuation proceeds in an orderly manner.

Fire rated cables are fitted to smoke alarms, lifts, fire doors, emergency and fire alarms and all areas in industrial and commercial premises where fire is a potential risk. There are different types of cables, each constructed differently and of different materials.

Heat-Resistant Cables

Heat-resistant cables are designed to operate normally in high-temperature settings. They are commonly used in such places as steel, ceramic and ironworks, in lighting technology, in ventilation and heating, electric motors, etc. Most are silicone sheathed copper cables used in high voltages. Basic cables running in residential buildings can stand up to 120°C, while the best heat resistant cables can operate up to 250°C without melting.

Fire Rated Cables

Fire rated cables differ from heat resistant cables in that they are tested according to specified fire standards and need to either stop the spread of fire or work when there is a fire present. Fire-retardant cables are constructed in such a way that they prevent the spread of flames along the cable length. Fire-resistant cables, go one step further in that they must maintain so-called Circuit Integrity of various electrical wiring, meaning they must operate normally when in direct contact with a flame. Fire-resistant cables can be further divided into 60, 90 and 120 minutes of fire resistance at a set temperature of 750°C or above. Cables pass testing if they are operational after the rated test period.

How Fire Rated Cables are Constructed

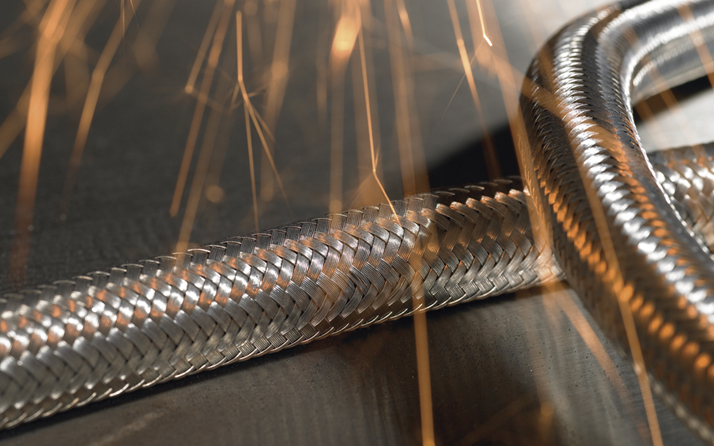

There are stark differences as to how fire rated cables are constructed. Construction also depends on the application of the cable. Differences in the conductor size and number, the types of insulation, cable screening and outer sheath determine the conditions in which the cables can be used. Fire retardant cables consist of annealed copper conductors insulated with reinforced polyethylene and surrounded by what is known as Low Smoke Zero Halogen (LSZH) thermoplastic sheathing. The sheathing is what stops the propagation of flames to other areas, while also releasing negligent amounts of smoke or toxic materials into the atmosphere (commonly found in cables with PVC sheathing). Fire-resistant cables have a similar construction, but also include Mica glass tape bounding a single core conductor or multiple conductors depending on the type and application of the cable. Higher fire resistance is achieved by a protective layer of metal armouring, either with aluminium, steel or solid copper under the LSZH sheath. Such cables can resist temperatures of over 900°C, over a period of two hours.

Where Fire Rated Cales are Used

Typical uses of fire rated cables are in emergency and fire systems. The wiring of fire alarms, voice alarms, emergency lighting circuits and power circuits in such industries as mining, gas and oil exploration, as well as public spaces like hospitals, schools, government offices, sporting venues and high-rise residential blocks, requires the use of fire-rated cable. Other areas where fire rated cables are standard are in communications and manufacturing. Data, coaxial and fibre-optic cables are now fire-rated and come in different build configurations. For manufacturing purposes, power and instrumentation cables are also fire rated. Smelters, kilns and furnaces are prime examples where high voltage fire rated mains and power cables are used in the production of metals, ceramics and glass among other products.

Fire Rated Cable Standards

Cables are rated according to different testing parameters and International and Australian Standards. Flame propagation, or the spread of the flame from the initial contact area is prevented by the outer sheathing of thermoplastic. Variants with no or low halogen content reduce the amount of toxic and corrosive gases when in direct contact with fire, so avoid the risk of suffocation due to smoke inhalation. Overall fire resistance is measured at set time frames and temperatures of 750 or 900°C. Different testing methods are used for cables set vertically and those that are set horizontally.

Final Thoughts

Heat resistant, fire retardant and fire-resistant cables are built differently and use varying levels of fire protection. Cable manufacturers have extensive lineups of fire-rated cable, each designed for specific applications. Datasheets include a detailed description of materials used, as well as fire resistance, flame propagation, smoke and toxic gas emissions measured according to set standards. Fire-rated cable is sold through cable and industrial retailers and wholesalers.