Advantages of Using Forged Pistons

Pistons have been used in combustion engines pretty much since engines were invented. They’re a core pillar of how auto engineering works, and it’s important that they are the correct fit for your car’s engine. However, typical cast pistons don’t always get the job done, which is why you should consider upgrading to forged pistons, which will definitely give you a significant boost to your engine so you won’t even have to check up on it that often. While cast pistons are usually good enough, if you want to get the most out of your vehicle’s engine, then you definitely should go for forged ones.

Manufacturing Techniques

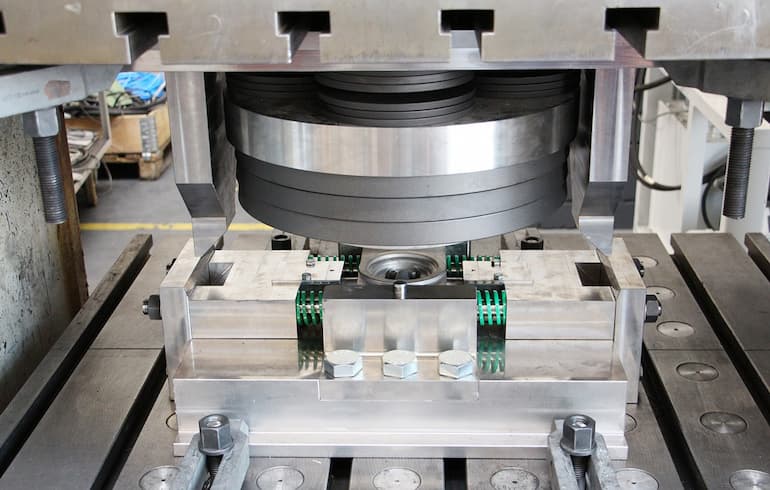

Not all engine pistons are created equally. The main difference between a cast and forged engine piston is the manufacturing process. That’s because the casting process is significantly cheaper, so it also entails creating a product that is of relatively lower quality. Cast pistons are created with large equipment that includes a mould in which a mixture of aluminium, alloys, and silicone is poured in order to shape the piston. In contrast, a forged engine piston utilises one lump of billet alloy that’s stamped by the use of a die. The shape and size of the piston itself are determined by the die. This is a much more costly process, which is why forged pistons are typically more expensive than cast ones. However, the forged pistons are also often of higher quality than their cast counterparts, which is why they’re recommended to enthusiasts and professionals to use in their vehicles.

Forged Pistons

As stated, professionals and enthusiasts prefer to use forged pistons due to a variety of factors, such as increased quality, better durability, longer lifespan, as well as great customisability, all of which play a vital role in fine-tuning the engine. You might need to have a fly-cut on the piston crown in order to assist in valve relief in some engine applications, which is typically achieved best by using a forged piston. On top of that, forged pistons are quite stronger and more durable due to the manufacturing techniques in play, which is mostly because of a larger surface area concentrated into its shape.

It’s a common misconception that forged pistons are difficult to manufacture. That’s not exactly true because there is no need to use heavy and specialised equipment that’s needed for their cast counterparts. It’s also untrue that cast pistons are inherently worse to use than forged one because it all comes down to what you need and the applications of the piston itself.

Characteristics

The forged piston’s defining characteristics are its strength and durability, which are the main reason why forged pistons are used in high-performance situations. In contrast, cast pistons contain a high amount of silicon, which is why they’re so brittle. Silicon gives metal lubricity and it’s then mixed in the alloy in order to limit heat expansion. Mild shock can cause the material to break, which is the main reason they need to be handled carefully. The forging process compresses the molecules in the alloy, which makes the piston’s area significantly denser and sturdier. Forged pistons are also heavier, but that’s because they can handle the engine’s high compression ratio, which allows the engine to produce more power. Most cars with turbochargers come with forged pistons because they can handle the engine’s increased performance.

Modified Engines

All certified engine builders agree that an engine with high compression or with an installed turbocharger will greatly benefit from having installed forged pistons. That’s partly because forged pistons allow for extra customisability, which works great in tandem with modified engines because forged pistons can be shaped into exactly what you need in order to gain maximum performance. That makes it ideal for them to be used in applications where you want to get specific performance out of your car’s engine, which is something that can’t be done with cast pistons.

Modified engines, by default, are subjected to more mechanical stress than stock engines, meaning they have to rely on sturdy high-quality parts in order for them to continue functioning. Due to the forged pistons’ added durability, they can definitely withstand the punishment that modified engines can dish out. It’s also worth noting that cast pistons can have great performance with mildly modified engines, as there is no inherent disadvantage at using them. Just make sure to consult with a professional before you commit if you’re not 100% sure you know what you’re doing.

Differences

So, it’s important to remember that there is no significant disadvantage of using cast pistons. While the materials aren’t as high quality as the materials used in forged ones, they are still good quality parts, provided the manufacturer has made sure of that. The main, and biggest difference to know is the manufacturing process. Forging and casting pistons each have different applications, with casting being a standardised process that follows specific rules across the industry. While there are absolutely standards with forged pistons, they can be customised in order to facilitate high-performance applications of the engine. Which one you’ll use is up to you, just make sure you make an informed decision before committing to either type of piston.