NC Turning Can Help You Give Your Business the Edge

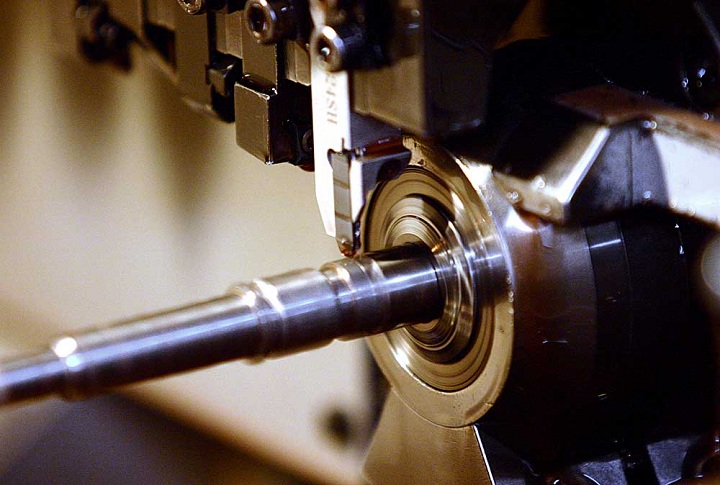

World of machining and manufacturing industries, NC turning machines will provide you with incredible advantages for a whole lot of different reasons. NC machines or Numerically controlled machines are basically tools that are automatically operated by top notch computers that are designed to read special code instructions in order to operate a specific tool. NC turning is a process which is used to shape the external surface of a certain object which can be made from wood, stone, metal, plastic, or composite materials.

Computer numerically controlled machines are a proof that companies should not fear the evolution of technology, but rather embrace it, if they want to stay relevant on the market and to get ahead in the component manufacturing industry. The manually operated machines such as boring machines, routers, lathes, mills, and so on, are now a relic of the past and they are holding some companies back. Switching to CNC machines will bring a number of benefits to your company.

Efficiency is one of the main reasons why these machines are so popular. They can be operated continuously virtually 24/7, 365 days per year. The obvious benefit of this, of course, is increased productivity and work efficiency. With manual manufacturing, the worker will often require toilet breaks, lunch breaks, or will simply need to run another errand which is not the case with NC machines.

Precision is another great benefit of CNC machines. They can repeat the same process over and over again in exactly the same time because you eliminate the human factor. In fact, there are some components which are so complex and practically can’t be manufactured manually. Moreover, it is required less training for people to operate a CNC machine. To operate manual machines, a great deal of training is needed, which takes a lot of time, money, and effort.

Another great thing about CNC machines is the fact that you can supervise multiple machines by a single worker at the same time. Basically once the program is switched on, you can leave the machine alone to do its job. There is the occasional replacing of tools and various components, but as I said, once switched on, they can be supervised by just one worker.

The only drawback of CNC machines is that they are costly to operate and maintain. However, there is a simple solution to that as well. You can always outsource the manufacturing of the components you need for your company, but that, of course, depends on the demand for components.

Overall, CNC machines will greatly boost the productivity of your company and launch it into the computer era.